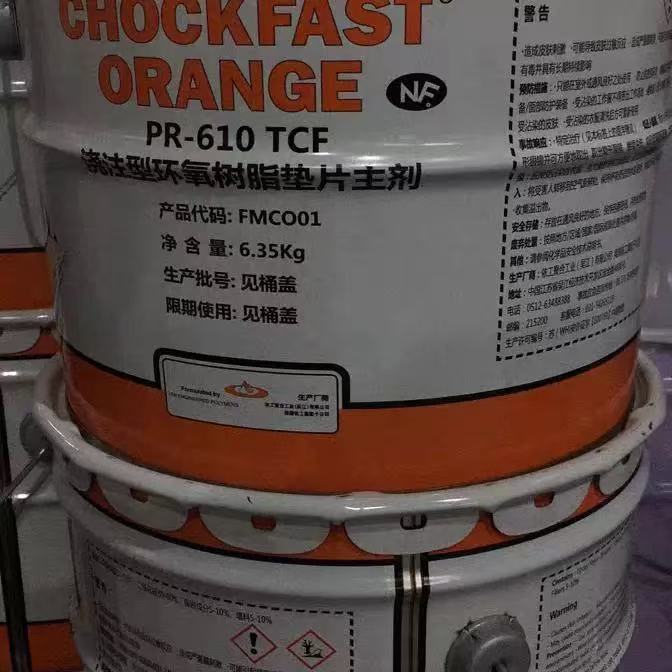

CHOCKFAST ORANGE RESIN PR-610 TCF

CHOCKFAST ORANGE RESIN PR-610 TCF Is a Special 100% Solid Two-component Inert Filling Casting Epoxy Resin Compound 3.4kg 2.13J.

315.625,00 Kz

Lead time 3 March 2026

In stock

Description

Product Overview

Chockfast Orange (PR-610TCF) is a meticulously formulated 100% solids, two-component inert filled casting compound. Engineered for use as a chocking or grouting material, it has been a game-changer in various industries due to its outstanding performance and reliability.

Exceptional Performance in Harsh Environments

Chockfast is designed to endure severe marine and industrial environments that involve a high degree of both physical and thermal shock. The compound is non – shrinking, which is crucial for maintaining the integrity of the equipment it supports. Its very high impact and compressive strength ensure that it can handle the rigors of heavy machinery operation and challenging working conditions.

Industry – Wide Approval

PR-610TCF has gained approval or acceptance for its intended marine use by renowned regulatory agencies such as the American Bureau of Shipping, Lloyd’s Register, Bureau Veritas, Det Norske Veritas, Germanischer Lloyd, and most other major regulatory bodies worldwide. This wide – spread recognition attests to its quality and suitability for critical applications.

Diverse Applications

- Marine Applications:

-

- Developed initially as a chocking or grouting compound for use under marine main propulsion machinery in depths ranging from 12 mm to 100 mm (½” to 4”).

-

- Commonly used under diesel and gas engines, reduction gears, generators, compressors, pumps, bearing blocks, and crane rails on ships.

- Industrial Applications:

-

- Applied in industrial machinery settings, providing a stable and reliable support for various types of equipment. It is suitable for use in factories, power plants, and other industrial facilities where precise equipment alignment is essential.

Advantages over Traditional Methods

- Ease of Use: PR – 610TCF requires no special tools or skills as compared to traditional steel chocking methods. When cast, Chockfast Orange flows readily into the chock area. It fills voids and conforms to all irregularities, eliminating the need for machining base plates or foundations to achieve a perfectly fitted chock. This not only saves time but also reduces labor costs.

- Cost – Effectiveness: Despite its high – performance capabilities, the use of PR – 610TCF has proven to be a more cost – effective method in the long run. By providing a superior and permanent solution for equipment alignment under extreme conditions, it reduces the need for frequent maintenance and realignment, thus saving overall costs associated with equipment operation

Technical Data of Chockfast® Orange (PR-610TCF)

|

Property Category

|

Property Name

|

Metric Value

|

English Value

|

Test Standard

|

|

Physical Properties

|

Specific Gravity

|

1.58 g/cc

|

1.58 g/cc

|

–

|

|

Mechanical Properties

|

Hardness, Barcol

|

≥40 (full cure)

|

≥40 (full cure)

|

ASTM D2583

|

|

Tensile Strength

|

34.3 MPa

|

4970 psi

|

ASTM D638

|

|

|

Flexural Strength

|

52.50 MPa

|

7615 psi

|

ASTM C580

|

|

|

Flexural Modulus

|

5.93 GPa

|

860 ksi

|

ASTM C580

|

|

|

Compressive Strength

|

131 MPa

|

19000 psi

|

ASTM D695

|

|

|

Mod Compressive Modulus

|

3.67 GPa

|

533 ksi

|

ASTM D695

|

|

|

Mod Shear Strength

|

37.2 MPa

|

5400 psi

|

Fed – std – 406 (method 1041)

|

|

|

Izod Impact, Notched

|

0.267 J/cm

|

0.500 ft – lb/in

|

ASTM D256

|

|

|

Thermal Properties

|

CTE, Linear

|

30.8 µm/m – °C @ 1.67 – 60.0 °C

|

17.1 µin/in – °F @ 35.0 – 140 °F

|

ASTM D696

|

|

Shrinkage

|

0.020% (linear)

|

0.020% (linear)

|

ASTM D2566

|

|

|

Processing Properties

|

Pot Life

|

≥30.0 min @ 21.1 °C

|

≥30.0 min @ 70.0 °F

|

–

|

|

Shelf Life

|

24.0 months

|

24.0 months

|

–

|

|

|

Descriptive Properties

|

Fire Resistance

|

Self – extinguishing

|

Self – extinguishing

|

ASTM D635

|

|

Shock Resistance

|

Pass MIL – S – 901C (Navy) high impact shock test, grade A, type A, class 1

|

Pass MIL – S – 901C (Navy) high impact shock test, grade A, type A, class 1

|

–

|

|

|

Thermal Shock

|

Pass 0 to 212 °F

|

Pass 0 to 212 °F

|

ASTM D746

|

|

|

Vibration

|

Meets MIL – std – 167

|

Meets MIL – std – 167

|

–

|

related products

2.603.160,00 Kz